As part of Open House New York, I toured the Brooklyn Army Terminal. It was built at the end of World War I and was a huge military base that was used to transfer people and materials from land to sea. It was built in an entirely utilitarian design and in the incredibly short time of 17 months. However, its utilitarian design is what I find incredibly interesting. Building B has this huge atrium with two sets of railroad tracks. Trains would travel directly into the building where material would be off and on loaded from various levels. There are several bridges connecting several buildings so that material could be moved between buildings on vehicles without interfering with the train traffic below. The atrium is dramatic, and I love that the concrete pour lines are visible.

Tag Archives: Engineering

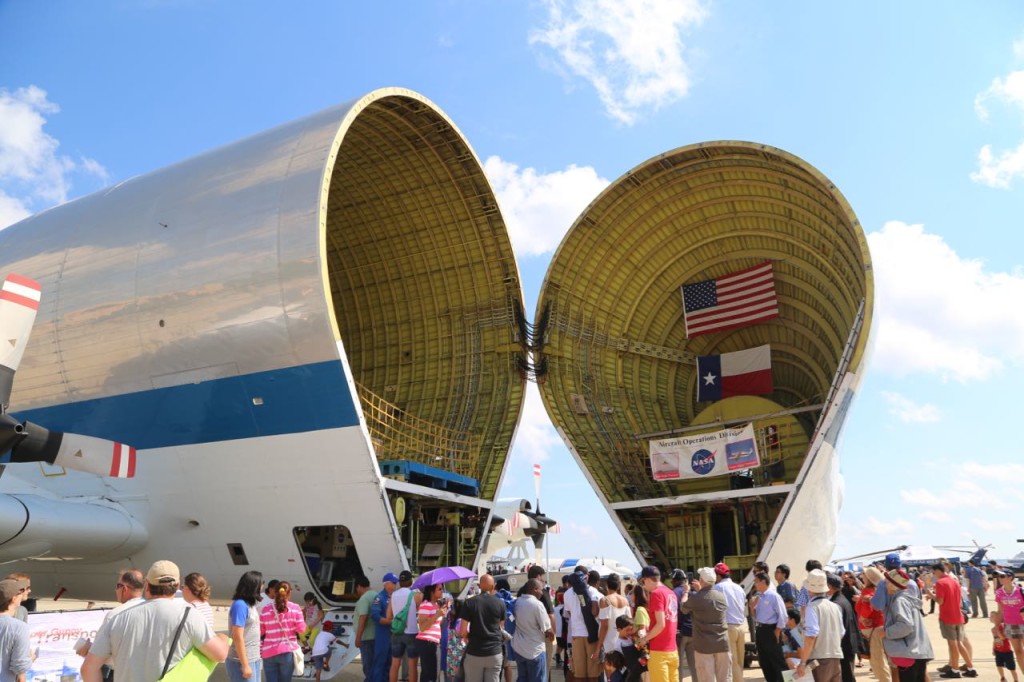

Joint Base Andrews Air Show

I went to the Joint Base Andrews Air Show today. It was awesome. There were lots of planes to view on the ground, but unfortunately you couldn’t enter all of them. Then there were incredible air shows demonstrations and acts in the air, appropriately. My only criticism is that the air show was already going to be causing air pollution because, well, planes, but then there was smoke that just seemed to be gratuitous air pollution cause by things on the ground. What can I say, I am an environmental engineer.

Newtown Creek

Newtown Creek is a natural creek that now resembles more of an industrial waterway and serves as a divider between Brooklyn and Queens in New York. I recently got a boat tour of it through Open House NY with superb guides from Newtown Creek Alliance and was able to see all the industrial facilities that are on it as well as a few places where its natural state is peaking through. Newtown Creek is heavily polluted because of New York City’s combined sanitary wastewater and stormwater system, which has led to untreated wastewater flowing into the creek during heavy rain events, and also industrial pollution, which has led to it being a Superfund site. A trip down Newtown Creek is almost history lesson down NYC’s past with some historic sites still visible like an old Standard Oil building. More modern parts of NYC also lie on the creek, most famously the newly redesigned and rebuilt Newtown Creek Wastewater Treatment Plant and its eight stainless steel digester eggs.

Marine Waste Transfer Station

I got the chance to tour New York City’s brand new Hamilton Avenue Marine Transfer Station. It is scheduled to open next year and is located on the Gowanus Canal in Brooklyn. It will be the transfer point for household waste from ten Brooklyn community boards. It is the first marine transfer station there. All other waste is moved on trucks and rail. It is very impressive. Once operational, it will operate 24 hours a day and six days a week (no Sundays). Currently waste from the area goes to waste to energy incinerators. There will be 12 sanitation workers per shift plus one supervisor.

Trucks enter the building and are first weighed on a scale.

Once inside the building, the trucks back up to the edge of the floor and lower their trash onto the mixing floor below.

Front loaders and other equipment on the floor below are used to push the waste through openings in the floor into containers waiting below the mixing floor.

Waste mixing floor with equipment to push waste into containers, the elevated floor on the left is where the trucks will lower their loads

The openings in the mixing floor are only as big as the standard containers that will accept the waste. The station aims to put 20 tons of waste in each container.

Once the container is full, equipment is then used to place a top on the waste container.

The containers are moved the loading area to the topping area to the storage area on rails.

Loading bay, in foreground are toppers and behind, with yellow frames, are where containers will sit to receive waste

Cranes that are also on rails are used to move the containers from the building to stacking areas to finally the barge.

There are two cranes, but for safety, only one is used at a time. The other one is a backup during maintenance.

NY Nostalgia Ride

I have been a member of the NY Transit Museum for a couple of years now, and they always have fun excursions. Some of the excursions, you probably have to be a transit geek to fully appreciate though. Anyway, today I took one of their nostalgia rides. It started in Grand Central Terminal where we boarded a vintage WWI rail car. We then went all the way down to the end of the 6 line, which is the Brooklyn Bridge station, then took the loop through the Old City Hall subway station, and came back up to our final destination of Pelham Bay Park station. There we boarded vintage buses to either Orchard Beach Park or City Island. We spent a couple of hours there before heading back to our vintage rail car and back to Grand Central Terminal.

The destinations were nice, and the ride was so much fun. The train and buses were in great condition. Honestly they were in better condition than some of the modern ones in which I have ridden. Since the journey was supposed to be part of the fun, they slowed down as we went by a few abandoned subway stations including the Old City Hall station. With the exception of the Old City Hall station, which they keep in good condition for tours, the other abandoned stations were completely abandoned and filled with graffiti and sand bags and debris. They also let people stand in the front and take photos out the front window, but I actually got better photos on a previous trip with them. Of course I still love looking.

Another wonderful thing about this trip was people’s reactions. My guess would be that about 80% of the people in the subways didn’t even see that a rather different train was going by or did see and didn’t seem to think much of it. Most of the rest would either look at the train with a rather confused look of “what is that?” or would quickly grab their camera and smile. There were a few people who are evidently transit fans and knew we were coming and were already set up with still and video cameras and some even with tripods. There was at least one at every aboveground station we went through, and there also some on the ground to get photos of the buses. As a certifiable geek and nerd, I can completely relate and and admire them. Then there were the MTA employees who seemed to be just as excited about the vintage train and buses as we were. They took as many photos as we did. This included workers repairing tracks who stopped what they were doing, took photos, and waved at us (see photo below). I am not even sure why we all get so excited about these vintage vehicles. Maybe it is because nothing mechanical or electrical seems to last that long anymore, so we are all excited by the things that do.

Istanbul: Basilica Cistern

The Basilica Cistern is without a doubt one of the coolest, human made places I have ever been. I don’t think you need to be an engineering nerd like myself to find the place to be really neat. It is an underground cistern built in 532 A.D. It is a wonderful example of engineering and was used to store water. Now it is a tourist attraction complete with a cafe. Yes, there is a cafe, and in my opinion, it would be only more perfect if it was a Starbucks simply because they are everywhere. The cistern was featured in the James Bond movie ‘From Russia With Love.’ Two of the columns have Medusa heads as bases, possibly because they fit and were available. There is still water in it below the walkways, and fish live there. They were introduced to keep the water clean.

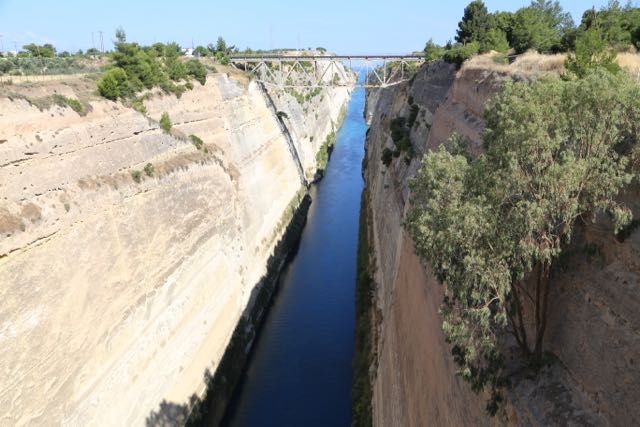

Greece: Corinth Canal

I’m an engineer. If there is a canal, dam, bridge, or whatever engineering marvel anywhere around, I have to see it. Luckily, our tour group had the Corinth Canal on the itinerary. The Roman Emperor Nero originally tried to build a canal to link the Aegean Sea with the Gulf of Corinth, but it was too difficult, so back then, they just dragged ships across the isthmus. I wouldn’t want to do the dragging. The Corinth Canal was started in 1881. No locks, just a canal, but wow, what a cut.

Being #DistractinglySexy

So here is the summary that you have probably have already heard, Tim Hunt, a Nobel laureate scientist made some very sexist remarks to of all people, a group of female scientists and engineers. He stated men and women shouldn’t work together in the same lab because when they do, you fall in love with them, they fall in love with you, and they cry when you criticize them. I think the man thinks a bit too highly of himself that any women he works with would fall in love with him.

The reaction mocking him, especially on Twitter, has kept my faith in humanity. Women have been tweeting photos of themselves working in the field and lab. Showing how distractingly sexy they are. I tweeted two photos of myself from HAZWOPER training, once in Level A PPE and one in Level B PPE.

Yes I know I am #distractinglysexy in my Level A PPE. The suit totally flatters my curves. pic.twitter.com/LUb5nXx9yO

— Geeky Girl Engineer (@gkygirlengineer) June 11, 2015

Here I am again being #distractinglysexy in Level B PPE. Because who can’t resist a girl with her own supplied air? pic.twitter.com/uCAwdtOm6R

— Geeky Girl Engineer (@gkygirlengineer) June 11, 2015

Those tweets have proved quite popular with the Level A photo thus far getting over 1100 retweets, and the Level B getting over 360 retweets. The tweets have been featured in articles in Buzzfeed, Washington Post, Salon, and Huffington Post UK. The whole thing has been rather surreal honestly. I have been contacted my media outlets to comment. I haven’t, partially because of timing and such.

I don’t even have any photos of me really working in the lab or field that would demonstrate how real work is the complete opposite of distractingly sexy. Well, I guess everyone find different things sexy, but get real. In the first part of my career I worked as a consultant. Typical field work included environmental site assessments where I was directing drillers to get soil and groundwater samples. Gloves, steel-toed boots, jeans, and a t-shirt that was likely going to get dirt on it were my “sexy” look. Then there was the time I was helping to sample a malfunctioning aeration chamber at a wastewater treatment plant in 95°F heat. [The aeration chamber is generally the start of secondary treatment, and thus there should be little to no smell. As this was malfunctioning, try to imagine the smell of raw sewage cooking in the heat.] If you find that situation sexy, well, I don’t think I want to meet you. Then there was the time I was checking on a pilot water treatment plant. Mainly it was a whole lot of sitting around, taking notes, checking valves, and taking some samples by myself. Normally field work involves a lot of sweating really. However, there was one time I was working in the field, again getting soil samples, in New Jersey in the dead of winter. There was no sweating or falling in love. There was just me freezing my butt off and making sure the security guards were in sight. That was a fun job; it was the only time I’ve ever been in a location where safety from crime was an actual issue. Normally the safety issues are the more mundane moving parts, heat, sun, fire ants, and then the one rattlesnake. God bless Texas.

When I was a Ph.D. student, we did our field work at auto body shops measuring the exposure the painters received to a chemical in the clear coat. Basically the shops were loud and smelly with really fun chemicals, and we sat around all day collecting personal air samples, tape strips from their skin after painting, all the urine we could get, and blood at the end of the day. In the hot months, there was sweating. In the cold months, there was shivering. At what point would we be distracting each other with our sexiness? Would the latex gloves and respirators, be the cause? No doubt the painters were falling in love with me because I kept trying to get them to drink more water and begging them for more urine. After the field work was done, I spent the better part of two years or possibly more in the lab analyzing all the urine samples. I analyzed over 400 urine samples, and the analysis was a three day procedure. The first part of the analysis involved adding concentrated sulfuric acid to the urine and then heating it for four hours to 100°C. Yes, nothing says distractingly sexy like urine cooked with acid. Luckily, the lab has hoods and other ventilation methods. Oh, and I shouldn’t leave out the part of asking my lab mates for their urine at times because I used that as unexposed urine from which to make my standards. How I did not fall in love with them while they handed me cups of their own urine, is anyone’s guess.

Now, I mainly work in an office. I get into the field every once in a great while. The photos I tweeted are from training, and I have never actually worn that level of PPE for real work. However a couple of weeks ago, I got into the field, and got to help sample fish, then watch a biologist sample them. I did not in fact fall in love with the biologist when he was filleting the fish.

Street Excavation

Early in my career as an environmental engineer, I sometimes did field work that involved soil and groundwater sampling. The type of soil sampling I did used shallow coring down to about 15 or 20 to obtain different depth soils to analyze for contamination. Number one rule before coring or digging for any reason, is to have all the utility marked. Most, if not all, states have a single number you can call and request the utility companies come out and mark where their underground pipes, wires, or whatever are. They would come and spray paint lines to denote their utilities, and then the drillers and I would know to avoid those areas. The sites I worked out were fairly simple, and avoiding utilities was pretty straightforward. Then there are old, densely populated cities like New York. I have never done any type of digging in New York City, and I hope I never do. The underground is a maze of pipes and wires and then below that are subways and basements and who knows what else.

I went to New York City this past Saturday. While walking around, I passed an area where the street had been excavated for utility work of some type. There were four guys cutting holes in a large diameter metal pipe. I asked one of them what the pipe carried, and he said it was for gas, but it had not been used in a long time. Because I am an engineering nerd, I of course had to take a bunch of photos, and what I saw confirmed my desire to never do any digging work there. My hat is off to the people who do. They must have to do the digging by hand, possibly with a tablespoon to get around all the pipes. The shoring looked like some crazy Tetris scene trying to put the beams around the pipes. The guys cutting the pipes had barely any room to work and that is not mentioning how they were bending down to cut.

So if you were ever curious just what types of utilities are below the streets of Manhattan, see below.

Waste to Energy Plant

Last week I got the chance to tour a waste to energy plant. The plant receives non-hazardous, household garbage from municipalities, consumer businesses, government agencies, and international ports. It burns the waste and converts the energy given off during the burning to electricity, which is then put into the power grid. Some of the waste that comes from government agencies need secure destruction, and at the plant, the waste is put directly into the feed stream and burned, so as to allow the needed secure destruction. The waste from international ports, such as nearby airports, must be burned to prevent any pathogens entering the country that may affect agriculture, and so it also is fed directly to the feed stream. Interestingly, the municipalities that send waste to the plant discourage their residents from putting yard waste into the trash. Besides being environmentally unfriendly because yard waste can be composted and nutrients returned to the earth, the yard waste is also not good for the waste to energy process because it produces nitrogen oxides (NOx), which forces the plant to put in more pollution control.

There are 88 waste to energy plants in the US, and 45-46 are Covanta’s, the owner and operator of this plant that I toured. The plant receives about 1000 tons garbage/day and after burning it, produces about 300 tons ash/day, which is 10-15% fly ash and the rest bottom ash. Thus, the plant achieves about a 70% weight reduction and also a 90% volume reduction. The fly ash is sent to monofill, which is like a landfill but only accepts fly ash. Fly ash can be used in making concrete, so evidently there is currently research being done by both the concrete industry and various waste to energy plants as to if this fly ash can be used for concrete and thus also be reused.

With the exception of the trash that has to go directly into the feed, when it first comes to the plant, the trash is placed on floor where humans look at trash to remove anything that should not be going into the boiler. For example, inert material shouldn’t go into the boiler because not only does it not burn, it is also a heat sink and reduces the efficiency of the process. The trash is then put into a storage pile to be eventually fed into the boiler feed. A large claw moves the trash to piles, mixes the piles, and then moves trash from the piles into the boiler feed.

The trash is sent to one of three boilers, each of which has six cells. The boilers burn the trash at 1800-2000°F (1300K). The boilers are initially heated up with diesel fuel, but then the trash sustains the burn. However everyday diesel fuel is used to test the burn.

The heat from the boilers is used to heat water to turn it into steam. The water is in a closed loop system, but they use about 20-25,000 gallons of water per day due to loss. [They use another 200,000 gallons/day for the cooling tower and are exploring with the nearby wastewater treatment plant using treated wastewater for this.] The water goes through a reverse osmosis treatment for purity, so nothing damages the turbines and the rest of the system. The produced steam is superheated but drops to 700°F before entering the turbines. There are two turbines with 14 stages. The steam turns the turbines, and that motion is converted into electricity in the generator. They produce 14.5 MW per turbine. Because of the work the steam does on the turbine, the steam enters the turbine at 600 psi and leaves in vacuum in a 10 ft length.

All the gases that leave the boiler pass through a series of air pollution control units. Ammonia, lime slurry, and carbon are used for pollution control. There are probes in the system to sample flue gas for pollution control additives that are needed. The treated gas then goes to a baghouse where particulates are captured. The air is below 300°F before going into baghouse, so it has cooled quite a bit.

The ash from the boiler is sent through a unit to remove all metals. The ferrous metals (attracted to magnets) are separated from the rest of the metals, and all the metals are sold for scrap.

The whole process is monitored in a control room by one or two people. I was amazed at how simple the process was. I, the environmental engineer, was of course geeking out at the whole thing, but it was a really cool process and efficiently run.

Finally here is a very short video of a few scenes from the plant. This includes waste being loaded into the feed, the fire in the boiler, and bottom ash entering the metals separator.