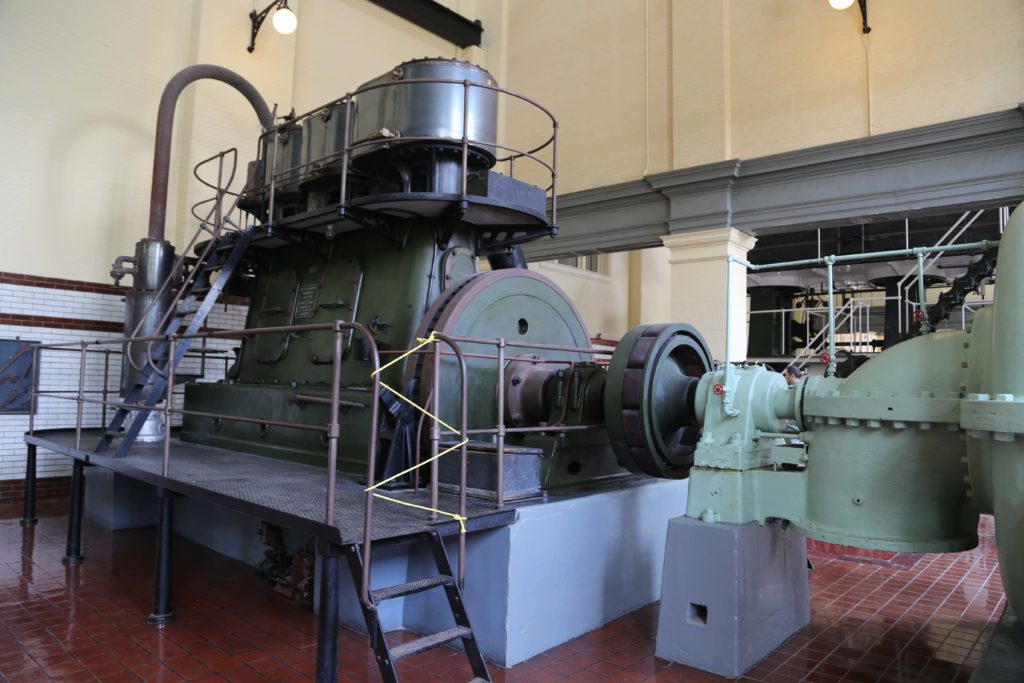

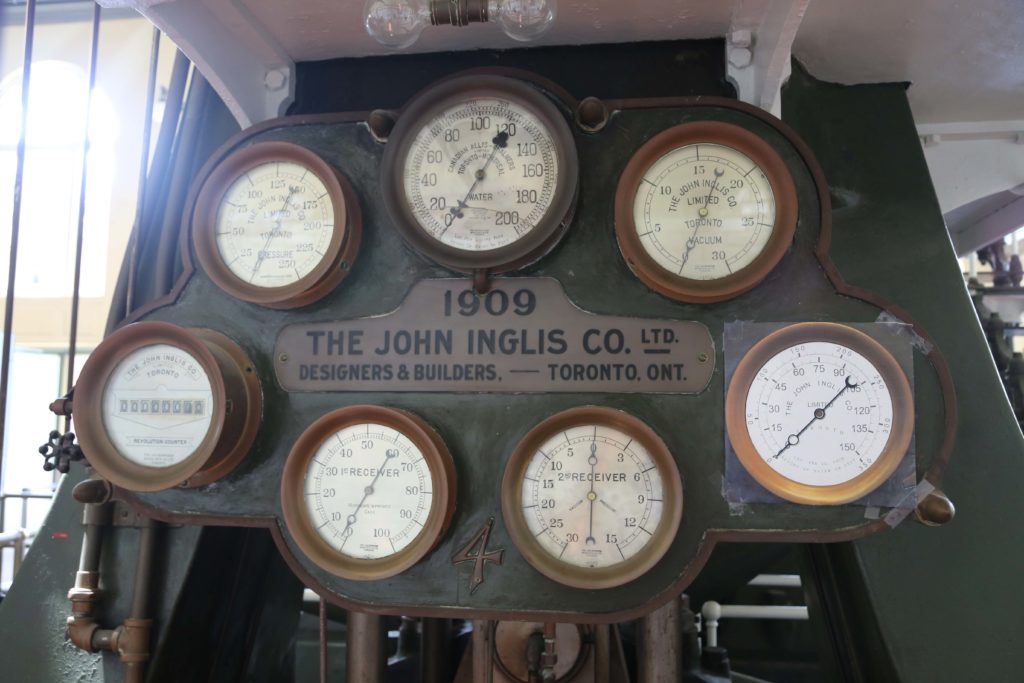

As part of Doors Open Toronto, I visited the High Level Pumping Station. It is the oldest building in Toronto’s water supply system. The oldest part of the building dates back to 1906 with other additions added later until the final one in 1953. The building houses a vertical triple expansion steam engine from 1909 with a huge crank and flywheel, not to mention a lovely set of huge wrenches hanging next to it. The building also houses a steam-geared centrifugal pump. However neither of those are used anymore but instead have been replaced with nine electric motor-driven pumps to fulfill the pumping station’s objection of conveying drinking water to that area of Toronto.

Tag Archives: Engineering

R.C. Harris Water Treatment Plant

As part of Doors Open Toronto, I toured the R.C. Harris Water Treatment Plant, which is not only the most beautiful water treatment plants I have ever visited, it is one of the beautiful buildings I have ever visited period. Colored stone and brass are everywhere. It was built in Arts Deco style, and in my opinion as an engineer, lays tribute to the importance of what the plant does, providing clean water to Toronto. It has two galleries with huge windows to allow viewing of the filtration chambers. In front of these windows are gorgeous stone tables with simple bronze control levers. The plant itself sits on hill overlooking Lake Ontario, where it gets its supply of water to clean.

Portlands Energy Centre

As part of Doors Open Toronto, I toured the Portlands Energy Centre. They produce electricity by two processes. First, they combust the natural gas, which turns gas turbines. Second they capture the heat from the combustion and use it produce steam, which then turn steam turbines. The gas turbines and steam turbine produce the actual electricity. They use Lake Ontario water as cooling water, but here is what I find interesting. They need ultra pure water to use in the equipment for cooling, so they have a multi step process to clean the water, including filtration, disinfection, reverse osmosis, and ion exchange. When that cooling water is later released to Lake Ontario, after being properly cooled, it is actually cleaner then when they pumped it into the plant. I followed the maze of pipes wondering how they ever find the right one when they need to do maintenance, and I desperately a process flow diagram, so I could follow everything along. When standing in the room with several pumps for the cooling water, the room was actually vibrating from the pump motion. Then of course, I started to wonder about the structural engineering and the amount of motion the structure has to be able to bear. Things an engineer thinks about, even when on vacation.

I took lots of photos because I find a beauty in the maze of pipes. It’s probably the chemical engineer in me. Some were labeled, so were not. Almost all were silver. This must make for a fun time when you need to pipe a specific pipe. However, there is a simple elegance, and please excuse me, but beauty in the pipes going everywhere, one next to another and a top another, in an orderly fashion. It is a maze but a logical maze. No mess. Just order.

Billy Bishop Airport

Billy Bishop Airport opened up its behind the scenes areas for Doors Open Toronto. The airport is located on a little island just off of downtown. By just off of, I mean late last year they opened a pedestrian tunnel connecting it to the mainland, so you can literally walk to the island. They pulled out a lot of the equipment they use for maintenance including snow removal and also for emergencies including fire fighting. They have so really cool equipment. One thing I found really interesting was that they don’t use a snow plow on the runways; they use a snow brush. The snow brush is better because of the short length of the runways. They use plows for taxi areas and places where cars go. The brushes also are used during the summer to remove rubber build up from the runways. Planes braking as they land leave rubber marks, and when enough builds up, it lowers the traction, so the rubber has to be removed. They spray a chemical to the runway, then come through with the brush to break up the rubber.

TTC Leslie Barns

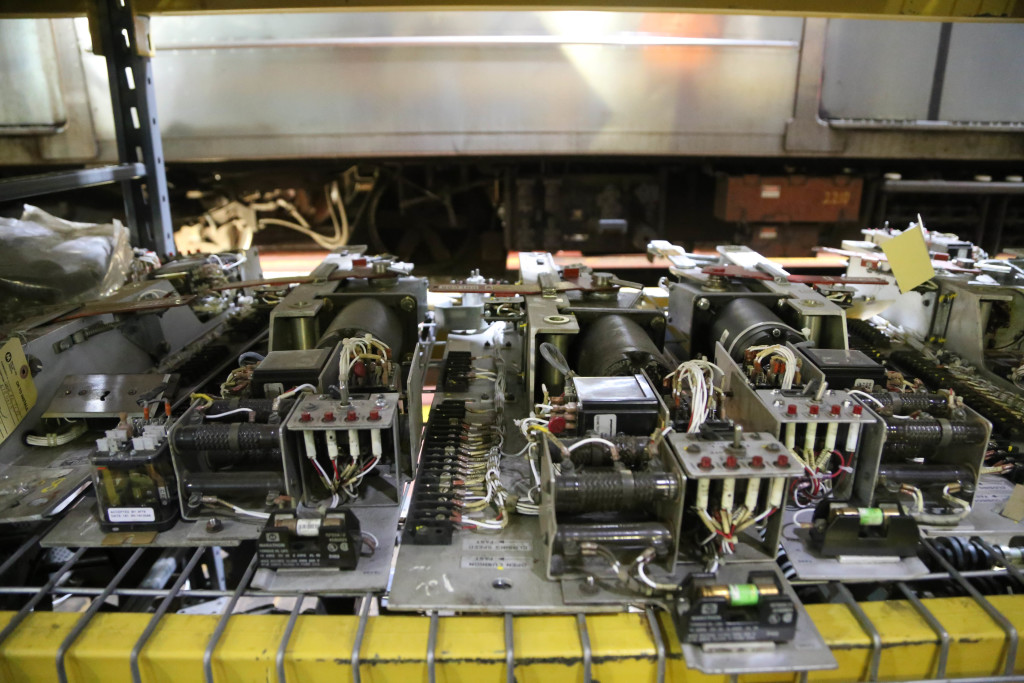

As a part of Doors Open Toronto, I got to tour Toronto Transit Commission’s (TTC) Leslie Barns. Leslie Barns is a streetcar maintenance and storage facility, and it is brand new. It is not completely finished, but it is already being used. I had to ask several employees about this because I find it difficult to believe that it is being used at all. It is without a doubt the cleanest, neatest, prettiest maintenance facility I have ever been in. If you look at my blog at all, you will see I have seen a few. I love touring them. This place is ridiculously clean and organized. The pipes are not only labeled, but they are also color-coded. It makes my chemical engineering heart go pitter patter. The facility was built for the new street cars that Toronto is purchasing, which are very sleek looking. The place has a paint booth, maintenance areas, and car wash for street cars. Outside is a storage area for the street cars, and in the middle of it is a stormwater retention pond.

Grand Avenue Central Maintenance Facility

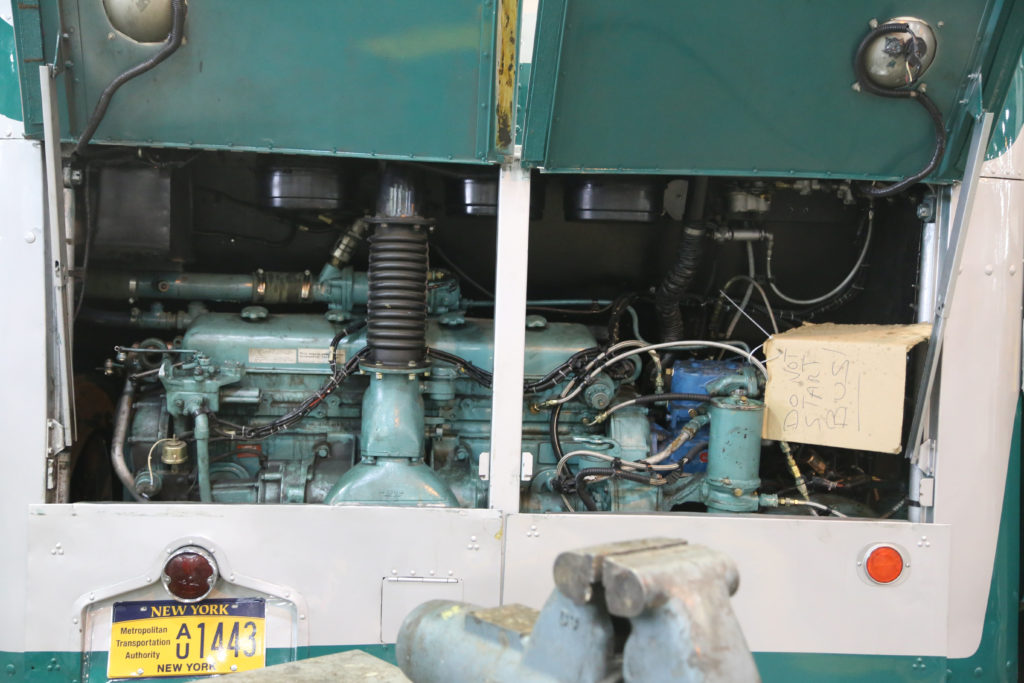

On the level above the Grand Avenue Bus Depot is the Grand Avenue Central Maintenance Facility, which can do repairs, overhauls, and painting of buses. It can also handle compressed natural gas (CNG) buses, which are not allowed in the bus depot below for safety reasons. The facility has storage of parts galore, two huge paint booths, and numerous bays for repairing buses. Also, at the time I was there, it had a vintage bus in for repair, which was really cool to see. There were also all these cool looking parts for the buses, none of which I could identify.

Grand Avenue Bus Depot

I toured the New York MTA’s Grand Avenue Bus Depot with the New York Transit Museum. The depot is relatively new, which is evident when you are inside. I don’t know much about bus depot design, but I was astounded by the amount of ventilation in the building. Considering the number of vehicles going and in and out every day, the ventilation is needed, but still I was surprised by the amount of it. The bus depot occupies the first level of this huge building, and the second level holds the Central Maintenance facility. They are considered to be different facilities. The bus depot is, well, a depot, or parking area for when the buses are not in use. The depot also where regular maintenance is performed and everyday activities like fueling, money removal, and washing.

I asked the facility manager what this garage style door was for. He looked at it and me and said he had never been asked that and wasn’t actually sure. Leave it to me to be able to stump people.

Confession: Other people in the group asked the depot manager to please let us go through bus wash, so he granted their wishes, and we all boarded a bus and went through a wash.

The ceilings and walls were almost completely filled with ventilation ducts, pipes, and conduits.

One of my favorite parts of the tour was learning that they vacuum money out of the fare box. MTA buses only accept coin and not bills. They hook up a hose to outlet at the bottom of the fare box, and the money is vacuumed out to secure boxes where it falls into bags or some other movable containers. The staff of the facility never touches the money. Then the money is removed from the boxes on a regular basis by armed staff. I think it is because I have a B.S. in chemical engineering that I found this so fascinating. We learned about pipes and other conduits and pump design for fluids. Coins are obviously not fluids. I am intrigued by the design that would be needed by items that are going to bounce around and not flow the way a fluid does. Also the pressure needed to pull coins out must be interesting.

It’s a Pipe

I went to a reception for a new(-ish) exhibit with the Culture Programs of the National Academy of Sciences. The exhibit are paintings by Jonathan Feldschuh that are inspired by the Large Hadron Collider. The paintings are acrylic on mylar, and they are quite gorgeous. While I’m sure my art-knowledgable friends will correct my terminology, to me, they look like impressionists paintings of very high-tech subjects. I love impressionism art, and of course, I love technology, so I really like these paintings. My friends R, J, and I were discussing this one painting that R and I both rather liked. I said I really like the way the perspective of the pipe or wires going off into the tunnel. I questioned whether it was a pipe or a bundle of wires. This is the conversation that ensued.

R: It’s not a pipe. It’s where the collisions occur.

Me: It’s a pipe then.

R: No, it’s not solid.

Me: Pipes aren’t solid.

R: Yes, but it’s different.

J: It’s more high tech.

Me: It’s a pipe.

R: There aren’t fluids flowing through it. It’s particles flowing through it and colliding.

Me: It’s still a pipe.

R: It’s not a pipe because the particles are in a vacuum.

Me: It’s a pipe. Those things at banks where the little container at the drive through is pushed through a pipe is pushed through a vacuum. It’s still a pipe.

R: [sighs] Ok, it’s a pipe.

It should be noted that according the CERN website, “The beams travel in opposite directions in separate beam pipes – two tubes kept at ultrahigh vacuum.” Thus, it’s a pipe. However, in R’s defense, I have a B.S. in chemical engineering, so everything is pretty much a pipe or a tank to me. Also, everything can be fixed with a hammer, but that is another story.

Communicating with Peers and the Public

I’m at a scientific conference currently. All day yesterday, I was in the same room listening to presentations on the same topic, mainly from people doing pure research, with some people doing research with more application objectives. At the end of the day, they brought several of the presenters together for a panel discussion. I had listened all day to many of the presentations, and I was growing somewhat concerned about the implications of some of the research. I support their research. I respect their research. I want to see more of their research. However I do not work in research, and where I work, communicating with the public can be very important. So I asked members of this panel a question. How are they going to explain to the public what they are doing. There is nothing unethical about what they are doing. They are doing good work that could lead to important information being revealed, but they are doing research in the real world, that quite frankly is not at this point meant for the real world. So I wanted to know, had they thought about how to explain the results of their research to the public? A member of the public who saw some of their data could become seriously confused and scared because they wouldn’t understand what the results mean.

I generally am not all that good at communicating. I am fine with public speaking if I have a script. However in public or even one on one, when speaking impromptu I many times stumble over my words. I sometimes have trouble getting all the thoughts in my brain to come out my mouth in a linear manner. I know it is a fault. I work on it. I have also been told by people that I sometimes talk at too high a technical level. I work on it.

So there I was at a scientific conference trying to ask people, many of whom I had known for a day or two, a question. I respect these people and their work. I am trying to ask a question and explain that members of the public might not understand their results. The irony is beyond rich. I, who have trouble communicating at times, who have trouble communicating at a level that others understands technical information, am trying to explain to my peers that they are doing work in a situation that members of the public can see their work, and members of the public will not understand their work.

Of course I stumble on my words. Of course I can’t explain myself clearly. And of course, these scientists I respect start getting defensive. They explain I don’t understand what they are doing. They try to explain what they are doing as if I have not already seen several presentations explaining what they are doing. One interrupts me before I can fully try to explain what I am saying. I explain I completely understand what they are doing, but members of the public won’t. I only want to know how they will explain their results to the public. I don’t want to argue with these people. I hate arguing. I just want them to understand my point of view. I stumble trying to explain. My heart starts racing so badly that I am shaking. I try to calm myself and explain differently what I am saying. A couple of people finally start to understand what I am asking. One responds “oh well, we will explain [jibberish].” I thought I had trouble communicating. No one would understand that.

A woman I have started to have a professional relationship with and have started to become friends with also was sitting next to me. Afterwards, she assured me she completely understood and had the same concern. Then several other people, who are not doing this research, came up to me and said they understood and shared my concerns. I thanked them for that. They have no idea how much I needed that. I hate arguing with people. I don’t want these researchers to think I don’t support their work. I want these people to like me, and I know we share a common goal.

I live and work by a couple of rules. I will not lie to people, and I will not put people in danger. Those are at the top of my list of rules. Telling people the truth is easier said than done when the truth involves highly complex information. It is difficult to explain what the results mean to the public when you don’t understand what the results mean. I work with some awesome people, some of whom take what I write and translate it so a normal person can understand it. I make sure it is technically accurate, and they make sure people can understand it. I understand the importance of communication. You have to tell people the truth, but you have to tell people the truth in way they can understand it. When you don’t understand what your truth means, you also have to tell people that truth.

NY 240th Street Yard

My most recent nerd trip to New York was to tour the New York City Transit Authority’s 240th Street Yard, also known as Van Cortlandt Yard. The train yard is completely elevated, which in my opinion makes for impressive structural engineering. It is a small shop, so it cannot hold all the trains that are out of service. The do regular maintenance as well as repair. I was impressed with all the safety mechanisms and protocols they have to make sure no one gets hurt.

Contact shoes (how the train makes contact with the 3rd rail). The one of the left is a snow shoe, the ridges cut the snow and ice, and the one on the right is a regular shoe.

Cables hanging in front of the car are “bugs”. The one with more cable and a 2nd box is a little bug because it has less voltage. The other one on the left is a big bug because it has more voltage and power the entire train.

A stick is used to make sure the contact shoe is at the right height. A maintenance worker is carrying another stick used to measure the height of the car above the rail.